How do linear induction motors work?

Think of linear induction motors (LIMs) as rotary motors that have been cut and unrolled to generate linear instead of rotary motion. Linear induction motors are comprised of two parts, the primary and secondary, which interact with one another only when power is applied. Either the primary or the secondary can be fixed while the other moves.

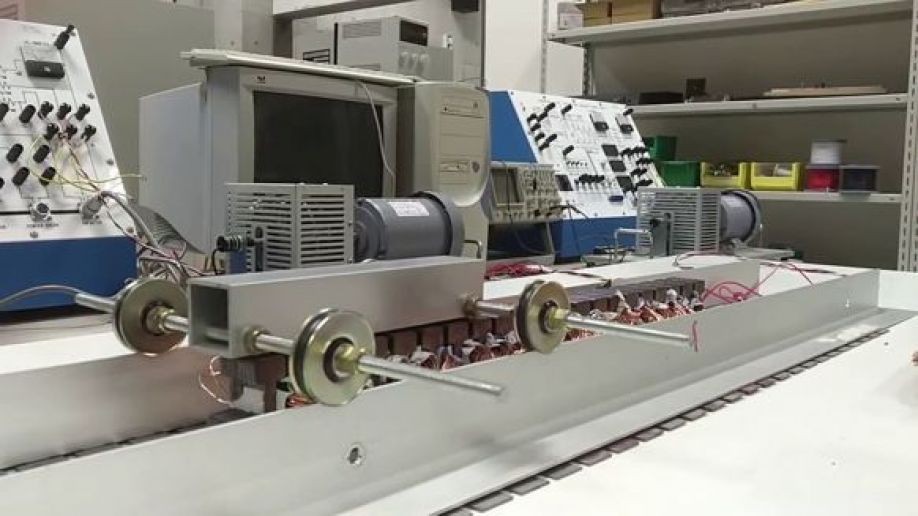

Image courtesy H2W Technologies

When three-phase ac power is applied to the primary, a traveling electromagnetic flux wave is induced and moves relative to the primary. The wave induces an electric current in the conductive reaction plate. The induced electric current interacts with the magnetic flux to produce a linear force. The speed of the motor can be varied by changing the input frequency using an adjustable frequency drive.

The primary consists of a three-phase coil assembly, equivalent to the stator of a rotary motor.

The three-phase coils are wound and inserted into a steel lamination stack along with thermal protection components. The coil windings and stack are then encapsulated in a thermally conductive epoxy.

The secondary, known as a rotor in a traditional rotary induction motor, is a reaction plate. This plate can be comprised of aluminum or copper, and a steel backing. The reaction plate length is equal to the length of the coil plus the stroke. A bearing system is required to maintain the air gap between the primary and secondary.

Linear induction motors can be manufactured in a wide range of force outputs, speeds, and footprints.

For single-sided assemblies, the reaction plate consists of 1/8-in. thick aluminum backed by a 1/4-in. thick steel plate, and for double-sided assemblies the reaction plate is 1/8-in. thick aluminum or copper only. If the reaction plate is round and it has a center shaft with rotary bearings, the system will produce rotary motion.

When you subscribe to the blog, we will send you an e-mail when there are new updates on the site so you wouldn't miss them.