GDPR (General Data Protection Regulation) adică Regulamentul General privind Protecția Datelor

Politica de confidențialitate ORIGINAL com prin raportare la noile reglementări privind protecția datelor

actualizare: 24 mai 2018

I. Informații generale

Confidențialitatea datelor dumneavoastră cu caracter personal reprezintă una dintre preocupările principale ale noastre, ORIGINAL com S.R.L. („ORIGINAL”), cu sediul în mun. Targoviste, str. Avram Iancu bl.24. sc.B ap.28, în calitate de operator de date.

Avem în vedere că, începand cu 25 mai 2018, va fi pus in aplicare Regulamentul (UE) 2016/679 privind protecţia persoanelor fizice în ceea ce priveşte prelucrarea datelor cu caracter personal şi privind libera circulaţie a acestor date şi de abrogare a Directivei 95/46/CE (Regulamentul general privind protecţia datelor) cunoscut ca si GDPR (General Data Protection Regulation). Asta inseamna ca orice Operator/entitate care prelucreaza date cu caracter personal trebuie sa aplice aceste noi cerinte si sa ofere intr-un mod transparent informatii cu privire la modul in care sunt prelucrate datele.

Prin acest document vă informăm cu privire la prelucrarea datelor dumneavoastră cu caracter personal, în contextul utilizării paginii de internet, www.original.ro

II. Categoriile de date cu caracter personal prelucrate

II.1. Dacă sunteți client al www.original.ro , ORIGINAL va prelucra datele dumneavoastră cu caracter personal, cum ar fi nume și prenume, telefon, adresa de e-mail, adresa de facturare, adresa de livrare, date referitoare la modul în care utilizați www.original.ro , de exemplu comportamentul/preferințele/obișnuințele dumneavoastră în cadrul site-ului nostru, precum și orice alte categorii de date pe care le furnizați în mod direct în contextul plasării unei comenzi prin www.original.ro sau în orice alt mod care rezultă din utilizarea www.original.ro.

Dacă, pentru a accesa www.original.ro utilizați contul dumneavoastră de Facebook, ORIGINAL va prelucra următoarele date publice de profil afișate de aplicațiile respective: nume utilizator, adresa de e-mail.

În cazul în care renunțați în a finaliza comanda unui produs disponibil pe comanda, adresa de e-mail și celelalte date furnizate nu vor fi stocate de ORIGINAL, iar datele dumneavoastră vor fi șterse automat.

II.2. Dacă sunteți vizitator al www.original.ro, ORIGINAL va prelucra datele dumneavoastră cu caracter personal pe care le furnizați în mod direct în contextul utilizării www.original.ro , cum ar fi datele pe care le furnizați în cadrul formularului pentru întrebări sau reclamații, formularului de returnare produs sau alte formulare, în măsura în care le completați.

II.3. Dacă aplicați pentru un job în cadrul ORIGINAL în calitate de candidat, prin accesarea secțiunii disponibilă pe site-ul nostru, ORIGINAL va prelucra datele dumneavoastră cu caracter personal pe care le furnizați în acest context, cum ar fi nume, prenume, adresa de e-mail, telefon, experiență precum și orice alte date incluse în documentele pe care alegeți să le încărcați în această secțiune.

II.4. Dacă sunteți persoană de contact a Partenerilor sau potențialilor Parteneri, ORIGINAL prelucrează datele dumneavoastră de contact, cum ar fi nume și prenume, adresă de e-mail și telefon pe care le furnizați în contextul inițierii sau desfășurării relației contractuale cu Partenerii sau potențialii Parteneri.

As it is mentioned in our presentation, Original company aims to strengthen its presence on the local market and the expansion of the company at an international level by providing solutions, products and services with a highly competitive value for money in the European market.

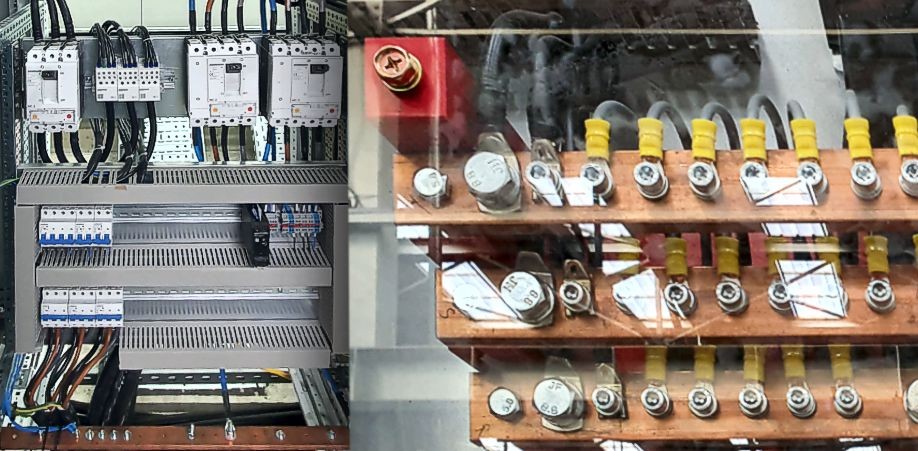

Our main interest is in the manufacturing of electrical cabinets (general electrical switchboards, medium and low voltage distribution switchboards, control and automation electrical panels, boxes and cabinets for distribution in low voltage, command, control and protection panels, command and control desks, measurement and protection blocks, etc.). We can do this type of projects both following the design provided by the client, and executing the project phase in our specialized department.

Another point of interest is represented by the distribution of products and solutions for automation through our store (physical and virtual) for both the Romanian and the regional markets. We are convinced that together we could carry out interesting projects that provide benefits for all the companies involved.

If your company is interested in a collaboration, please contact us through our interactive form, mentioning the subject of your interest and adding all the details that you consider appropriate (attached files, etc).

The project consisted of the realization of a monitoring and control system for the tempering and quenching processes and included:

- design

- mounting (in own workshop)

- supply

- installation

- commissioning

- testing

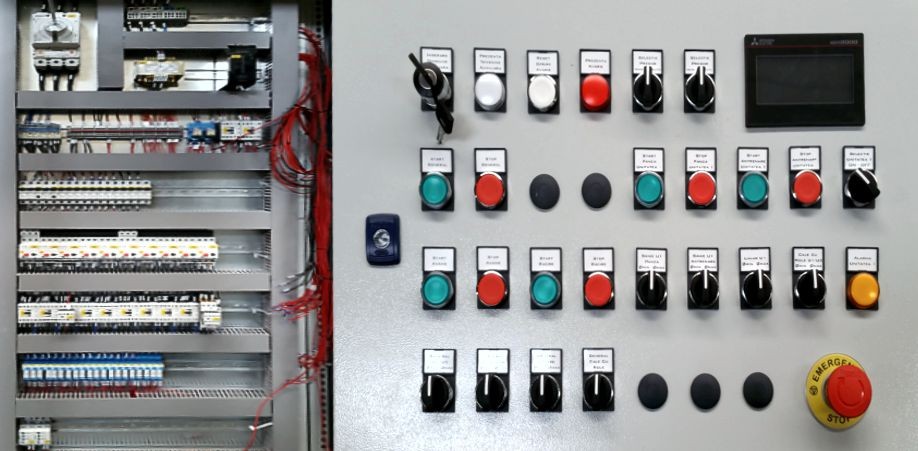

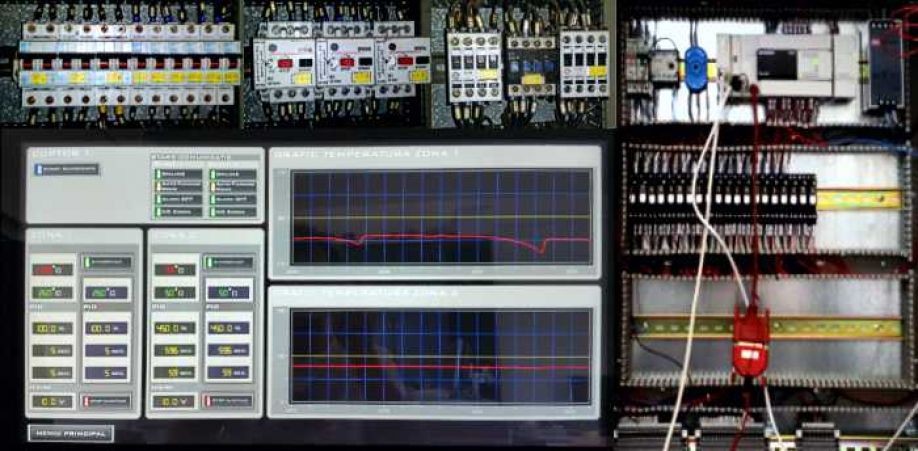

The electrical command and control cabinet allowed the beneficiary to perform starting, stopping and permanent monitoring of the process, depending on the temperature of the baths.

The automation of the process involved the installation of a switchboard equipped with a PLC and, in accordance with the beneficiary requirements, was agreed upon a solution that is flexible, reliable and perfectly adapted to the application specifications.

The system variables, alarms and graphs are displayed on a monitor in the operator cab and the application implemented is SCADA type.

The project consisted of the realization of a monitoring and control system for the neutralization process and included:

- design

- mounting (in own workshop)

- supply

- installation

- commissioning

- testing

The electrical command and control cabinet allowed the beneficiary to perform the on-line monitoring and control of the entire process: starting/stopping pumps, opening and closing of the valves, display sensors values for pH, conductivity, level, etc., process control and monitoring based on the sensors values, transfer between tanks, tanks drainage systems, filtration systems etc.

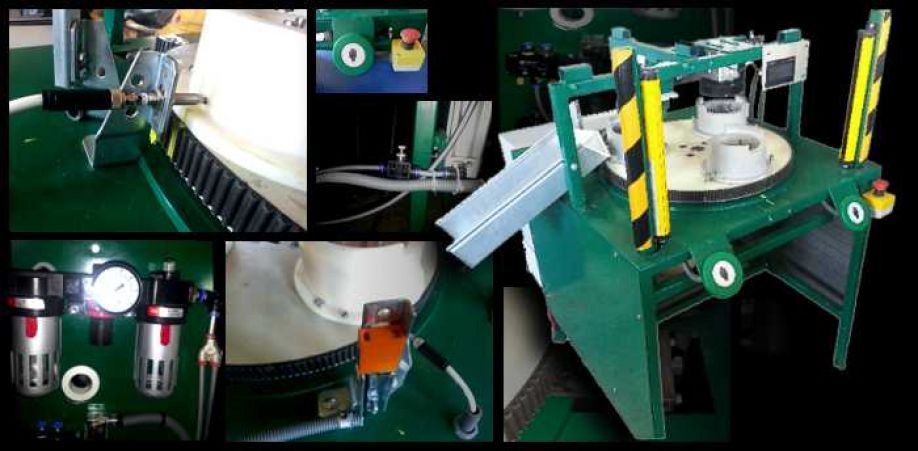

The project is to provide a machine for assembling components - clamping ring connection press, and involved:

- design

- mounting (in own workshop)

- testing in our own workshop

- packaging

- labeling

- delivery to France - the company headquarters - the complete machine, including the mechanical and pneumatic parts and the electrical and automation components

The machine is used for assembly operations using a pressing and automatic removal system of connection rings for the final plastic product. The connection rings press is equipped with pneumatic cylinders for the operations of pressing, with an automatic evacuation system for the assembled piece and with a servo-drive for the angular motion.

The security in operating system was done through the integration of a system of protection with optical safety barriers, which stop the functioning of the press when it detects a presence in their field of action. The clamping rings press was manufactured on a metallic structure, made of rectangular tubes joined together by welding and bolts. The plate for fixing the molds was made of polyamide and has been obtained by a milling process, in a numerically controlled machine.

From the electrical point of view, the press is controlled by a logical controller (PLC) and the calibration, control and monitoring of the parameters are performed by means of an HMI screen.

The project realization and control processes meant to go through all phases of a project of this type, such as:

- Acquisition of equipment, materials and their preparation for installation / mounting / machining

- Manufacture of the metal structure of the press and other components

- Installation of electrical equipment

- Mounting of mechanical and pneumatic parts, accessories, electrical components and other subsets

- Testing subsets

- Final control in our own workshop

- Packing machine for your shipment, labelling and completion of final documentation

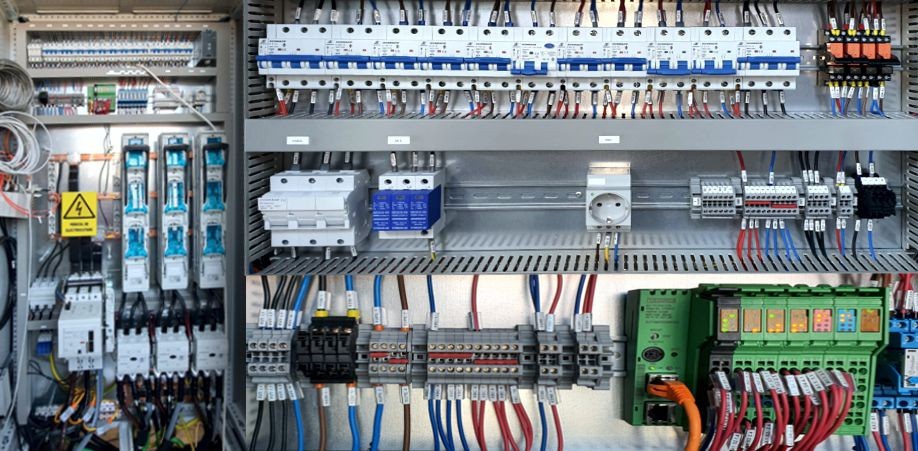

Under the generic title "Automation and control production lines", the company ORIGINAL conducted a series of projects that have involved automation, command and control of a large number of lines and technological processes of the beneficiary.

In these projects, after gathering all necessary information and all beneficiary specifications, were carried out the following activities:

- designing

- manufacturing of electrical distribution, command and control, consoles, etc in our own workshop

- transport and installation to final location

- punere în funcțiune

- commissioning and testing of equipment and technological lines.

The variety of topics covered led to accumulation of valuable experience and allowed us to subsequently provide beneficiary under its systems maintenance, a constant of our work, the professionalism and total commitment in all our actions.

Were made the entire electrical distribution and automation for:

- chrome plating lines

- high-frequency hardening lines

- grinding lines

- neutralization processes

- leveling machine line

- peeling lines

- the power distribution from the output of the medium voltage transformers to the field equipment

- the command and control for the field elements of each technological line, like: sensors, limiters, motors, valves, etc.

Monitoring and process control was achieved with SCADA systems, which allow both supervision and control processes and obtaining statistics on production systems and alarms generated.

In this project, the company ORIGINAL has developed a hardware and software solution that met the demands of the beneficiary to have a tool for the energy consumption monitoring.

In this project has been carried out the following activities:

- design

- development

- installation

- commissioning

- testing

- maintenance of the system

Based on the open source software Grafana, the application allows the monitoring of the energy consumption in substations and process lines: for data storage and system applications was installed a server and implemented a communications network based on Modbus protocol.

Data provided by the application are those specified by the client: total active power, apparent power and total tension and are displayed on the screen as graphics. The system implemented can provide other information (current, power factor, etc.).

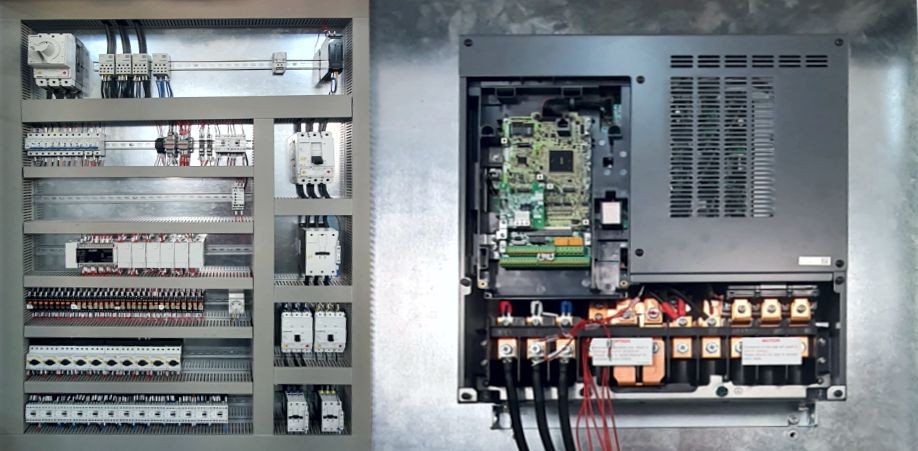

ORIGINAL company offers turnkey, innovative and high quality automation solutions based on the latest technologies, with the aim of improving production processes, both economically (extending the useful life of the installations and systems, increasing work efficiency by means of process automation, reducing losses and consumption of electricity, etc.), and in terms of the impact on human resources (by improving the working conditions of users, negative impact on the environment, simplification of the supervision, operation and control of the facilities processes, etc.).

Our activities cover all phases of the project:

- Electrical system and automation solution design

- The development of the software applications proposed in our solutions

- The implementation of the solutions established with the client

- Commissioning and tests

- Specialized Technical Assistance

- Preventive and corrective technical maintenance for customer-owned installations, systems and equipment

Currently the automatic regulation of systems involves an integrated approach to technological issues. The term "Mechatronics" is attracting increasing attention and is being used in an increasing number of systems and engineering applications and refers to the combination of precision engineering, electronic control and the integrative philosophy in the design process of manufacturing systems and processes. It is an interdisciplinary subject that is based on basic engineering, but at the same time it includes disciplines not directly related to the basic disciplines.

The basic concept in this definition is the idea of envisaging the system as a whole. This involves designing and optimizing the system as a whole and not as a sequence of incremental steps. Teamwork is essential in the design of mechatronic systems. The specialists of SC Original SRL in the fields of mechanics, electricity, control and information technology cooperate in all phases of design with the aim of converging into an integrated solution.

The variety of functions and processes within the installations and the industrial electrical systems generates the need to have software and hardware components that can manage the activities developed as efficiently as possible. From this perspective also, it is absolutely necessary to perform an integration of the various components in order to ensure a unified work environment, with an adequate flow of information between the different parts, at the same time allowing a low cost of operation and maintenance.

The design of integrated systems involves first of all an analysis of the specifications of each facility / machinery / equipment for a better understanding of the processes to be modified and also the identification of the customer’s general and specific requirements which allows us to be aware of the

needs in each project.

Once this initial stage is completed, the design phase of the integrated system will be carried out in two phases, that is the general design and the detail engineering.

The following will be established among other things: the overall architecture of the whole solution, the method of dividing the customer’s requirements into the components and subsystems of the solution, the inputs and outputs of the system, the connections between the different modules, and the physical model will be carried out and the comprising equipments will be defined, etc.

Another key element in the design of integrated systems is the communication infrastructure which has to be chosen and dimensioned accordingly to ensure the necessary traffic, all functionalities for the established number of users / operators and in order to apply the security policies to guarantee the confidentiality of information exchanged within the system.