The project is to provide a machine for assembling components - clamping ring connection press, and involved:

- design

- mounting (in own workshop)

- testing in our own workshop

- packaging

- labeling

- delivery to France - the company headquarters - the complete machine, including the mechanical and pneumatic parts and the electrical and automation components

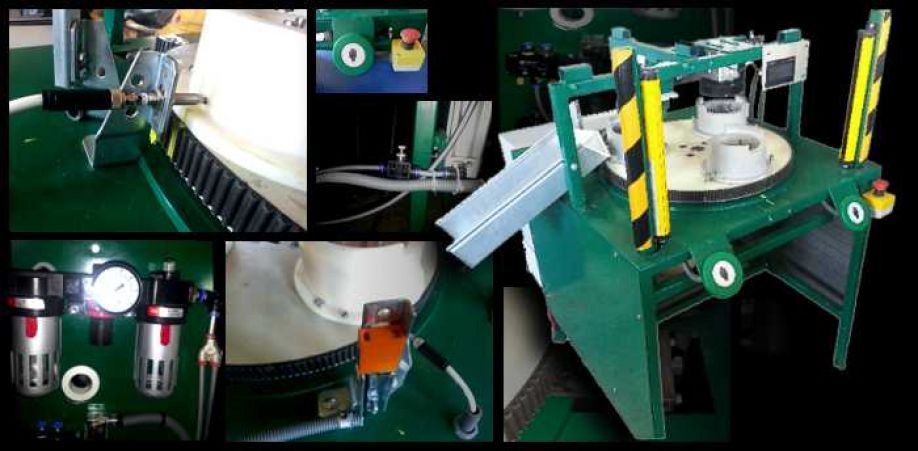

The machine is used for assembly operations using a pressing and automatic removal system of connection rings for the final plastic product. The connection rings press is equipped with pneumatic cylinders for the operations of pressing, with an automatic evacuation system for the assembled piece and with a servo-drive for the angular motion.

The security in operating system was done through the integration of a system of protection with optical safety barriers, which stop the functioning of the press when it detects a presence in their field of action. The clamping rings press was manufactured on a metallic structure, made of rectangular tubes joined together by welding and bolts. The plate for fixing the molds was made of polyamide and has been obtained by a milling process, in a numerically controlled machine.

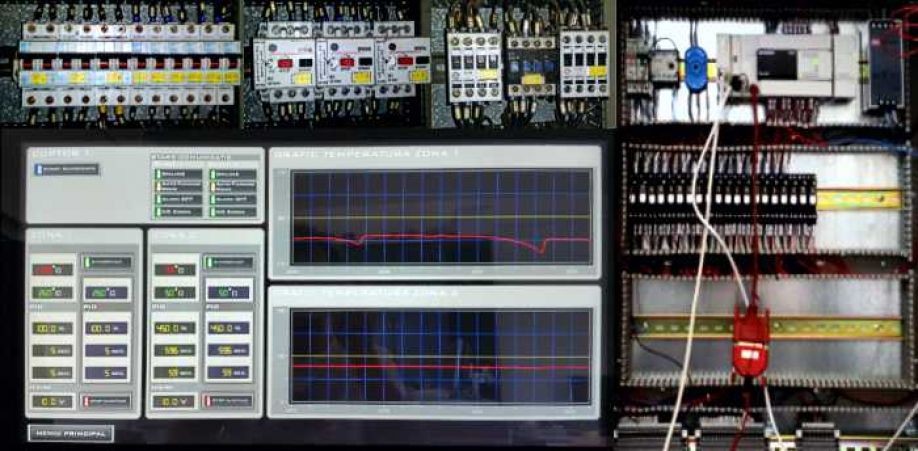

From the electrical point of view, the press is controlled by a logical controller (PLC) and the calibration, control and monitoring of the parameters are performed by means of an HMI screen.

The project realization and control processes meant to go through all phases of a project of this type, such as:

- Acquisition of equipment, materials and their preparation for installation / mounting / machining

- Manufacture of the metal structure of the press and other components

- Installation of electrical equipment

- Mounting of mechanical and pneumatic parts, accessories, electrical components and other subsets

- Testing subsets

- Final control in our own workshop

- Packing machine for your shipment, labelling and completion of final documentation